Manufacturing is experiencing its most profound transformation since the Industrial Revolution. In 2025, artificial intelligence isn't just optimizing individual processes—it's orchestrating entire factory ecosystems with precision that surpasses human capability. The smart factories emerging from this AI revolution aren't just more efficient; they're fundamentally different in how they operate, adapt, and evolve.

The shift goes beyond automation to true intelligence. Modern AI-powered manufacturing systems predict equipment failures before they occur, optimize production schedules in real-time based on demand fluctuations, and automatically adjust quality parameters to maintain perfect output. The result is manufacturing operations that are simultaneously more productive, more flexible, and more sustainable than ever before possible.

The Smart Factory: Beyond Traditional Automation

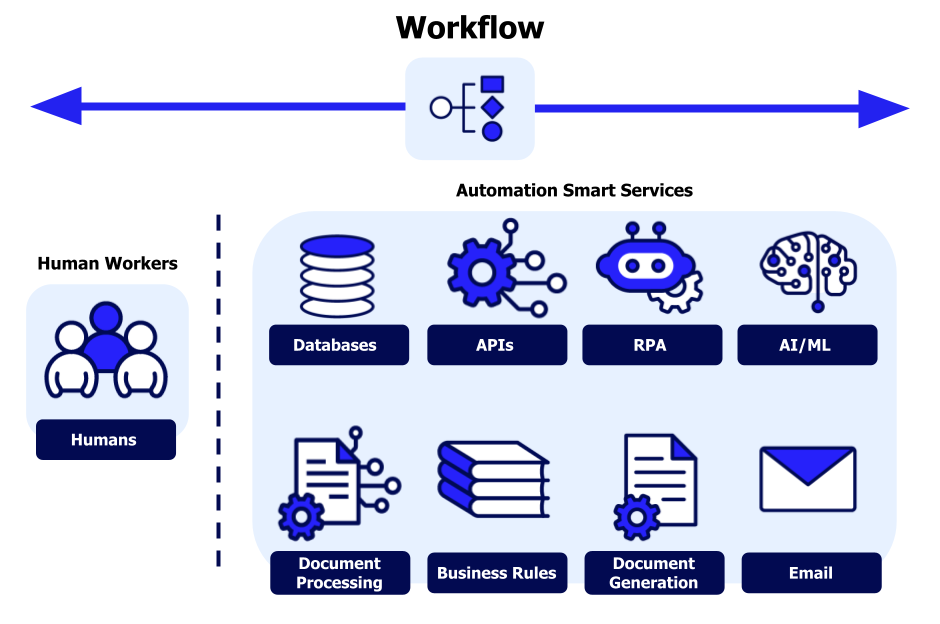

Traditional manufacturing automation focused on replacing human labor with machines that could perform repetitive tasks more consistently. Smart factories powered by AI workflow automation represent a quantum leap beyond this approach. These systems don't just follow programmed instructions—they learn, adapt, and optimize continuously based on real-time conditions.

Consider the difference in approach: Traditional automation might run a production line at a fixed speed with predetermined quality checks. AI workflow automation continuously analyzes dozens of variables—material properties, environmental conditions, equipment performance, demand forecasts, and energy costs—to optimize every aspect of production in real-time. The system might slow production slightly to improve quality when detecting material variations, or accelerate output when energy costs are low and demand is high.

AI Manufacturing Impact in 2025

The Five Pillars of AI-Powered Smart Manufacturing

The most successful AI manufacturing implementations in 2025 are built on five core capabilities that work together to create truly intelligent production systems.

🔮 Predictive Maintenance

AI systems that monitor equipment health in real-time, predicting failures weeks before they occur and automatically scheduling maintenance during optimal windows to minimize production impact.

🎯 Adaptive Quality Control

Intelligent quality systems that learn from every product produced, automatically adjusting parameters to maintain perfect quality even as materials and conditions change.

📊 Real-Time Optimization

Systems that continuously optimize production schedules, resource allocation, and energy usage based on real-time demand, costs, and operational conditions.

🔄 Intelligent Supply Chain Integration

AI that coordinates with suppliers and customers in real-time, automatically adjusting production based on supply availability and demand forecasts.

🌱 Sustainability Optimization

Systems that minimize waste, optimize energy usage, and reduce environmental impact while maintaining production targets and quality standards.

🧠 Continuous Learning

Manufacturing systems that improve over time, learning from every production run to enhance efficiency, quality, and reliability continuously.

Predictive Maintenance: The Foundation of Smart Manufacturing

Predictive maintenance represents one of the most transformative applications of AI in manufacturing. By 2025, leading manufacturers have moved beyond scheduled maintenance to truly predictive systems that understand the health of every component in real-time.

How Modern Predictive Maintenance Works

AI systems continuously monitor thousands of data points from sensors throughout the factory—vibration patterns, temperature fluctuations, acoustic signatures, power consumption, and performance metrics. Machine learning algorithms analyze these patterns to identify subtle changes that indicate developing problems, often weeks before traditional methods would detect issues.

The system doesn't just predict failures—it recommends optimal maintenance timing based on production schedules, parts availability, and technician capacity. This approach has reduced unplanned downtime by an average of 43% while cutting maintenance costs by 28%.

Real-World Implementation: Automotive Manufacturing

A major automotive manufacturer implemented AI-powered predictive maintenance across their production lines with remarkable results. The system monitors over 15,000 sensors across 200 pieces of equipment, predicting failures with 94% accuracy up to 30 days in advance.

Case Study Results:

- Downtime Reduction: 67% decrease in unplanned equipment failures

- Cost Savings: $2.3M annually in reduced maintenance and lost production costs

- Efficiency Gains: 23% improvement in overall equipment effectiveness

- Quality Improvement: 45% reduction in defects caused by equipment issues

- ROI Achievement: 312% return on investment within 18 months

Intelligent Quality Control: Zero-Defect Manufacturing

AI-powered quality control systems in 2025 have achieved what was once considered impossible: zero-defect manufacturing at scale. These systems use computer vision, machine learning, and real-time analytics to inspect every product with superhuman precision while continuously learning and adapting to new quality challenges.

Modern quality control goes beyond detection to prevention. AI systems analyze the relationships between process parameters and quality outcomes, automatically adjusting production settings to prevent defects before they occur. When quality issues do arise, the system traces root causes instantly and implements corrective actions across the entire production line.

Advanced Computer Vision Applications

Computer vision systems now inspect products with accuracy that exceeds human capability by orders of magnitude. These systems can detect microscopic defects, measure dimensions to sub-millimeter precision, and identify quality issues that would be invisible to human inspectors.

More importantly, these systems learn from every inspection, building increasingly sophisticated models of what constitutes quality. They can identify subtle patterns that indicate developing quality issues, enabling proactive adjustments before defects occur.

The Architecture of Smart Factory AI

Understanding the technological architecture behind smart factories helps explain how these systems achieve such remarkable results. Modern AI manufacturing systems are built on layered architectures that combine edge computing, cloud analytics, and real-time decision-making capabilities.

Smart Factory Technology Stack

Real-time KPI monitoring, strategic decision support, and performance analytics

Machine learning algorithms, predictive models, and optimization systems

Edge computing, stream analytics, and immediate response systems

ERP connectivity, supply chain integration, and data harmonization

Equipment monitoring, environmental sensors, and data collection systems

Industry-Specific Applications and Results

AI workflow automation delivers different benefits across manufacturing sectors, with some industries experiencing more dramatic transformations than others. Understanding these patterns helps manufacturers identify the most promising opportunities for implementation.

Aerospace Manufacturing: Precision and Compliance

Aerospace manufacturers are using AI to maintain the extreme precision and documentation requirements of their industry while dramatically improving efficiency. AI systems track every component through the manufacturing process, automatically generating compliance documentation and predicting quality issues before they impact critical systems.

Results include 89% reduction in quality escapes, 45% improvement in first-pass yield, and 67% reduction in compliance documentation time.

Electronics Manufacturing: Speed and Flexibility

Electronics manufacturers leverage AI for rapid product changeovers, dynamic scheduling, and micro-defect detection. AI systems can reconfigure production lines for new products in minutes rather than hours, while maintaining quality standards that exceed human capability.

Typical results show 78% reduction in changeover time, 92% improvement in defect detection, and 34% increase in overall throughput.

Food and Beverage: Safety and Efficiency

Food manufacturers use AI for safety monitoring, quality consistency, and waste reduction. AI systems monitor every stage of production for contamination risks, optimize recipes for consistency, and minimize waste through precise demand forecasting.

Industry results include 96% improvement in safety compliance, 43% reduction in waste, and 28% improvement in production efficiency.

Implementation Strategy: From Pilot to Full Deployment

Successful AI manufacturing implementation requires a strategic approach that minimizes risk while maximizing learning and results. The most successful manufacturers follow proven deployment strategies that ensure smooth transitions and rapid ROI.

Phase 1: High-Impact Pilot Projects

Start with pilot projects that have clear business value and measurable outcomes. Common high-impact starting points include predictive maintenance for critical equipment, quality control for high-value products, and energy optimization for major consumers.

Phase 2: Horizontal and Vertical Scaling

Once pilot projects prove successful, scale both horizontally (across similar equipment or processes) and vertically (integrating with upstream and downstream systems). This approach builds on proven success while expanding impact.

Phase 3: Full Ecosystem Integration

The final phase involves creating fully integrated smart factory ecosystems where AI systems coordinate across all aspects of manufacturing, from supply chain to customer delivery.

Calculating Manufacturing AI ROI

Manufacturing AI investments typically show positive ROI within 12-18 months through multiple value streams:

- Reduced Downtime: Average savings of $50,000-$200,000 per avoided failure

- Quality Improvements: Typical reduction of 60-90% in defect-related costs

- Energy Optimization: 20-35% reduction in energy consumption

- Labor Efficiency: 25-40% improvement in productivity per worker

- Inventory Optimization: 30-50% reduction in working capital requirements

Overcoming Implementation Challenges

While AI manufacturing offers tremendous benefits, successful implementation requires navigating several common challenges. Understanding these obstacles and their solutions is crucial for achieving optimal results.

Data Quality and Integration

Manufacturing environments often have disparate systems with inconsistent data formats. Successful implementations invest in data standardization, quality monitoring, and integration platforms that create unified data views for AI systems.

Workforce Adaptation

AI doesn't replace manufacturing workers—it transforms their roles from reactive problem-solving to proactive optimization. Successful implementations include comprehensive training programs that help workers adapt to new AI-augmented workflows.

Legacy System Integration

Most manufacturers have significant investments in existing equipment and systems. Modern AI solutions are designed to integrate with legacy systems through APIs, IoT sensors, and edge computing devices that don't require complete system replacements.

The 4rge4business Manufacturing AI Solution

At 4rge4business, we've developed a comprehensive AI manufacturing platform that addresses every aspect of smart factory operations. Our solution combines predictive maintenance, intelligent quality control, and real-time optimization in a unified system that integrates seamlessly with existing manufacturing infrastructure.

Our platform doesn't just automate processes—it creates intelligent manufacturing ecosystems that learn, adapt, and optimize continuously. The system provides manufacturers with unprecedented visibility into their operations while automatically optimizing for efficiency, quality, and sustainability.

Key Features of Our Manufacturing AI Platform:

- Predictive Maintenance Engine: Monitors 500+ parameters per machine with 95% accuracy

- Computer Vision Quality Control: Detects defects with sub-millimeter precision

- Real-Time Production Optimization: Adjusts parameters automatically for optimal efficiency

- Energy Management System: Reduces consumption by 25-40% through intelligent scheduling

- Supply Chain Integration: Coordinates with suppliers and customers in real-time

- Comprehensive Analytics Dashboard: Provides actionable insights for continuous improvement

Looking Ahead: The Future of Smart Manufacturing

As we progress through 2025, several emerging trends are shaping the next evolution of AI-powered manufacturing. Companies that understand and prepare for these trends will maintain competitive advantages in operational efficiency and market responsiveness.

Autonomous Factories: Fully autonomous manufacturing systems that require minimal human intervention while maintaining perfect quality and efficiency.

Mass Customization: AI systems that enable cost-effective production of highly customized products without sacrificing efficiency.

Sustainable Manufacturing: AI-optimized processes that minimize environmental impact while maintaining profitability and quality.

Resilient Supply Chains: AI systems that predict and adapt to supply chain disruptions automatically, maintaining production continuity.

The smart factory revolution is not a future possibility—it's happening now. The manufacturers that embrace AI workflow automation today will set new standards for efficiency, quality, and sustainability while achieving competitive advantages that compound over time. The question isn't whether to implement AI in manufacturing, but how quickly you can deploy it to stay competitive in an increasingly intelligent industrial landscape.